Close

Our in-house quality lab is equipped with high-precision instruments to inspect even the

most demanding components. From micro-level measurements to chemical composition

checks, we leave nothing to guesswork.

Every product goes through strict inspections at every stage using advanced tools:

Vision Measurement System (VMS) - Micro-level accuracy

Profile Projector & Magnascope – Visual perfection

Spectrometer - Raw material chemical analysis

Micrometres, Vernier’s, Thread & Radius Gauges - Precision in every

measurement

Height & Depth Gauges - Ensuring depth and flatness to specification

Inspection reports and certificates available on request

fully approved quality systems in place

Traceability and batch control from raw material to dispatch

At SHREE SOMNATH OVERSEAS, quality is not an afterthought — it's a mind-set. Every

component we manufacture reflects our core values of precision, consistency, and

responsibility. Whether it's a complex turned brass fitting or a high-volume metal part, we

engineer quality at every step from raw material to final inspection.

But machines alone don’t ensure excellence. Our quality is backed by a highly trained team

that understands both technology and craftsmanship. From material testing to final

inspection, every step is controlled, verified, and recorded—ensuring full traceability and

total reliability.

Our advanced production setup and in-house quality lab ensure that every piece leaving our

facility is ready for real-world performance.

Because for us,

Quality isn’t about finding faults—it’s about building perfection.

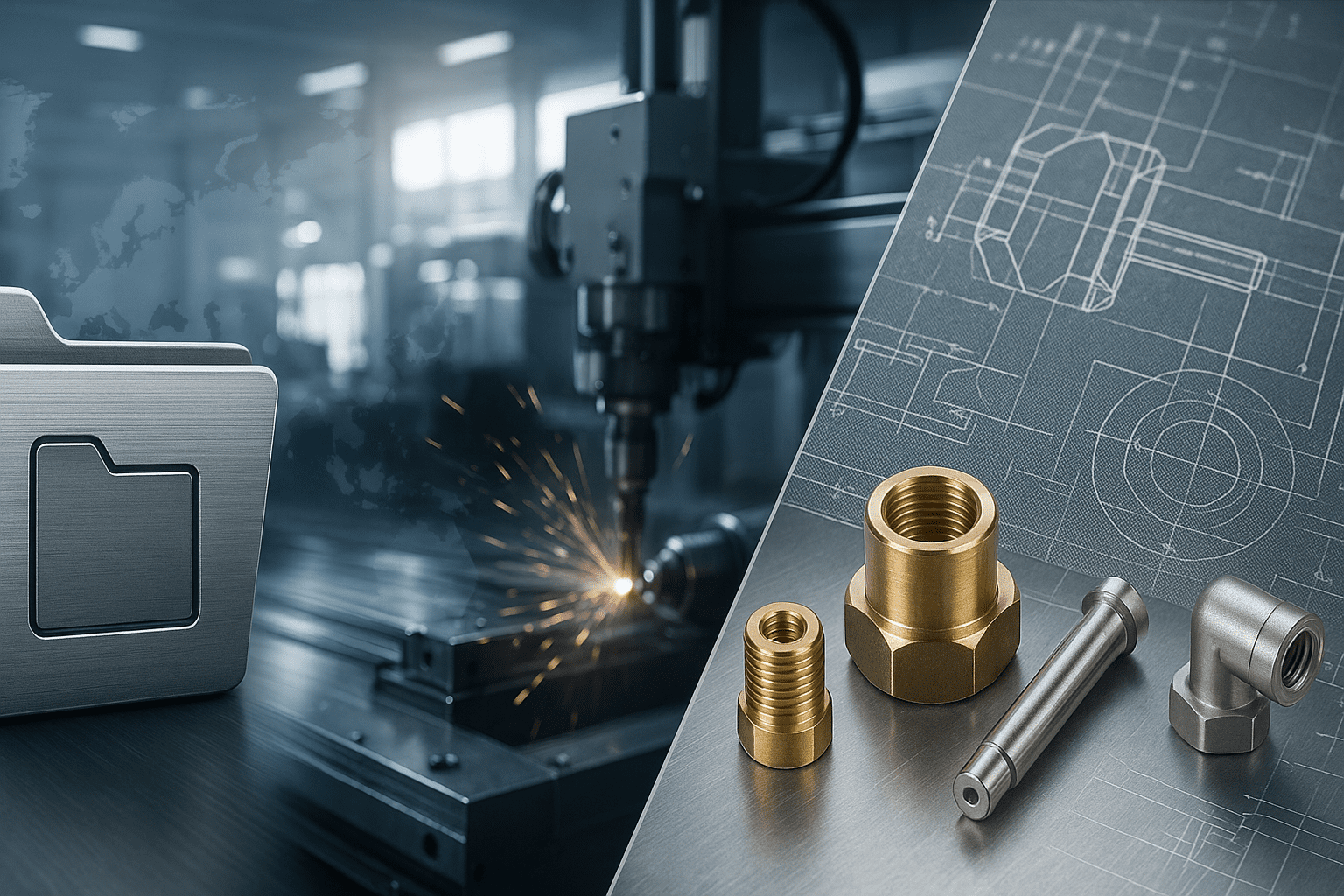

Our manufacturing strength With our modern machine setup, we turn complex requirements into flawless components

Our CNC (Computer Numerical Control) and VMC (Vertical Machining Center) machines offer high-precision, automated machining solutions designed to meet the demands of modern manufacturing.

Special Purpose Machines (SPMs) are custom-built machines designed to perform specific tasks or processes that standard machines cannot handle efficiently.

Efficient machines designed for high-volume turning of small to medium parts. Ideal for mass production with fast, consistent output and minimal operator input.

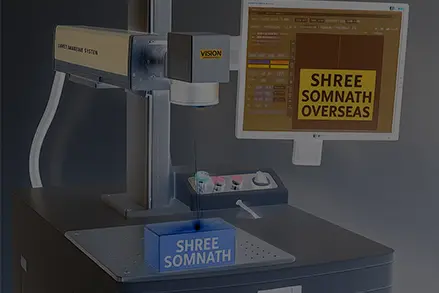

High-precision laser machines for permanent marking on metal, plastic, glass, and more - ideal for branding, barcodes, and custom designs with fast, reliable performance.

Our advanced Turn-Mill Centers (TMC) combine the precision of CNC turning with the flexibility of milling in a single compact setup. ex- Precision shafts, brass fittings, hydraulic connectors, aerospace parts, and more.

Our quality work ensures accurate threads and holes for metal, industrial parts, and custom assemblies, boosting performance and efficiency.

Our ISO certification reflects our uncompromising commitment to quality, safety, and continuous improvement across all operations.

This globally recognized certification ensures that every product we manufacture, and every service we deliver, is aligned with international benchmarks.

From raw material inspection to final dispatch, our processes are system-driven, transparent, and client-focused.

Why it matters to you:

Reliable quality, every time

Streamlined and traceable manufacturing

Dedication to improvement and innovation

At Shree Somnath Overseas, we collaborate, customize, and craft components that power industries across the globe. Whether it's a single prototype or high-volume production, we're ready when you are.

No minimums. No limits. Just possibilities.

From Jamnagar to the World — Let’s Start Building, Together.

Talk to Us