Hydraulic Hose Fittings Parts are critical components in hydraulic systems that help connect hoses to pumps, valves, cylinders, and other parts of the hydraulic circuit. These fittings are designed to create secure, leak-free connections that can withstand the high pressures typically found in hydraulic systems. Their role is crucial in ensuring the safe and efficient operation of various machines and equipment in industries like construction, agriculture, manufacturing, and transportation.

Types of Hydraulic Hose Fittings

Hydraulic hose fittings come in various types, each tailored to specific applications and requirements. Some common types include:

- Crimp Fittings: These are attached to hoses by crimping or compressing a metal sleeve around the hose to secure the fitting in place. They are widely used for high-pressure applications.

- Reusable Fittings: Designed for easy removal and reattachment, reusable fittings don’t require special crimping equipment. These fittings are often used in lower-pressure applications or field repairs.

- Push-On Fittings: Used for low-pressure hydraulic applications, these fittings can be manually attached without tools. They are easy to install but are limited in terms of pressure handling.

- Flared Fittings: In these fittings, the end of the hose is flared to create a tight seal when connected. They are commonly used in low- to medium-pressure hydraulic systems.

- O-Ring Face Seal (ORFS) Fittings: ORFS fittings have an O-ring in the face of the fitting, creating a strong, leak-resistant seal. They are ideal for high-pressure and high-vibration environments.

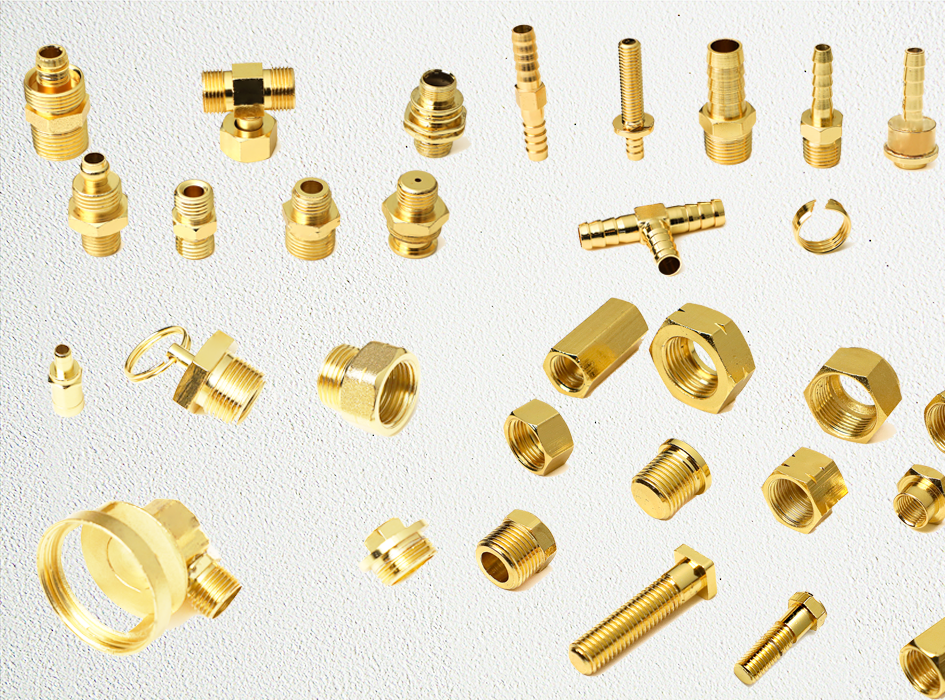

WE PRODUCE WIDE RANG OF ALL KINDS METAL COMPONENTS

AND WE ARE LEADING MANUFACTURER OF INDIA.

Materials and Construction

Hydraulic hose fittings are typically made from materials such as carbon steel, stainless steel, brass, or aluminum, each chosen for specific properties like strength, corrosion resistance, or weight. Stainless steel is commonly used in marine or harsh environments due to its excellent resistance to corrosion, while brass is often used for lower-pressure applications or in corrosive environments where high resistance is needed.

The design and construction of the fittings allow them to withstand the extreme conditions found in hydraulic systems, including high pressures, temperature fluctuations, and exposure to chemicals and oils.

These fittings must meet stringent industry standards to ensure safety and reliability, including international specifications like SAE (Society of Automotive Engineers), ISO (International Organization for Standardization), and DIN (Deutsches Institut für Normung)

Maintenance and Safety

Proper maintenance of hydraulic hose fittings is vital to ensure system performance and safety. Regular inspection of fittings for signs of wear, corrosion, or damage is essential. Any issues, such as leaks or cracks, should be addressed immediately to avoid system failures.

Applications of Hydraulic Hose Fittings

Hydraulic hose fittings are used in numerous industries and applications, including:

- Construction Equipment: Hydraulic systems are a backbone of construction machinery like excavators, bulldozers, and cranes. These machines rely on hydraulic power to lift heavy loads and move earth.

- Agricultural Machinery: Tractors, harvesters, and other agricultural equipment use hydraulic systems for various tasks, such as lifting, cutting, and steering.

- Manufacturing: In factories, hydraulic systems power machines used for pressing, stamping, molding, and lifting.

- Automotive and Transportation: Hydraulic systems are used in vehicles for braking systems, power steering, and suspension systems.

- Aerospace: Aircraft utilize hydraulic systems for landing gear, flight control surfaces, and braking systems.