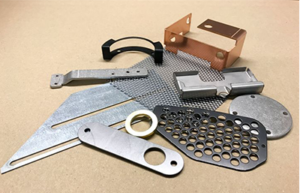

Sheet Metal Parts are essential components used in a wide variety of industries, including automotive, aerospace, construction, electronics, and manufacturing. These parts are fabricated from thin, flat pieces of metal, typically steel, aluminum, copper, or stainless steel, and are shaped into specific forms using processes like cutting, bending, stamping, and welding.

Sheet metal parts are prized for their versatility, durability, and cost-effectiveness. They can be manufactured in large quantities with precision, making them ideal for mass production in industries that require high-performance components. Common examples of sheet metal parts include enclosures, brackets, panels, chassis, and structural components.

We provide product as per RoHS norms and any size as per customer demand.

In the automotive and aerospace industries, sheet metal parts are used for body panels, frames, and other structural elements due to their strength and lightweight properties. In electronics, they provide housing for devices, offering both protection and aesthetic appeal.

Additionally, advancements in metallurgy and manufacturing technologies have enhanced the performance of metal components, offering better corrosion resistance, lightweight alternatives, and improved longevity. Their resilience and adaptability make metal components a cornerstone of industrial development.

Advances in fabrication technologies, such as laser cutting and CNC machining, allow for high precision and customization of sheet metal parts. These advancements have expanded their applications across industries, where reliability, precision, and performance are critical. The durability and adaptability of sheet metal make it a cornerstone in modern engineering and manufacturing.

Advantages of Sheet Metal Parts

- Versatility: Sheet metal can be formed into almost any shape, making it suitable for a wide variety of applications across different industries.

- Cost-Effective: The processes involved in sheet metal fabrication allow for mass production, reducing the overall cost per part, especially in large quantities.

- Durability: Depending on the material, sheet metal parts can offer excellent strength, corrosion resistance, and longevity, making them ideal for harsh environments.

- Precision: Modern technologies like CNC machining and laser cutting ensure that sheet metal parts are manufactured with high precision, meeting tight tolerances and complex design requirements.